Synthetic Roof Underlayment - A Modern Roofing Solution

Roofing is a critical aspect of any construction project, and a reliable roof underlayment is an essential component to ensure the longevity and durability of the roof. Traditionally, asphalt-saturated felt paper has been a popular choice for roof underlayment. Over the next few years, it appears that more homes will be covered with synthetic roof underlayment due to its benefits.

George EvansAug 18, 2023101 Shares33741 Views

Roofing is a critical aspect of any construction project, and a reliable roof underlayment is an essential component to ensure the longevity and durability of the roof. Traditionally, asphalt-saturated felt paper has been a popular choice for roof underlayment. Over the next few years, it appears that more homes will be covered with synthetic roof underlaymentdue to its benefits.

In this article, we will explore synthetic roof underlayment in detail, examining its features, applications, and the advantages it offers over traditional felt paper.

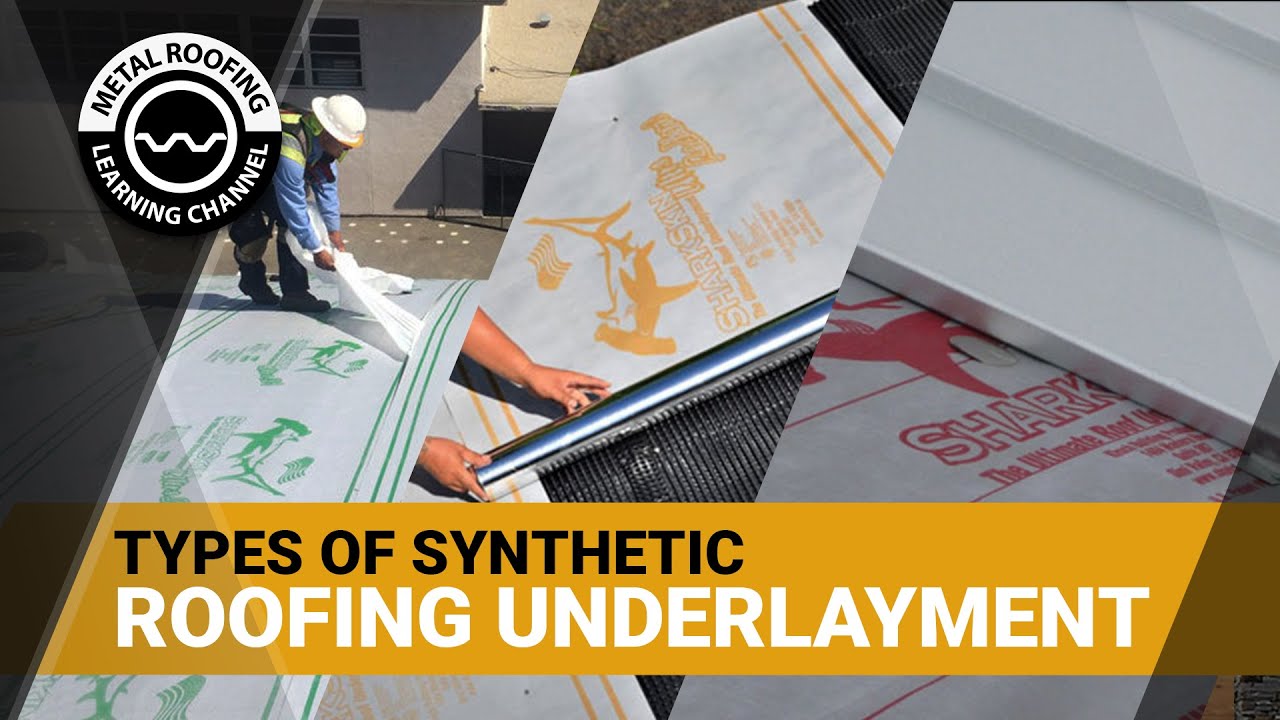

Synthetic Roof Underlayment

Synthetic roof underlayment, also known as synthetic roofing felt or synthetic roofing underlayment, is an advanced alternative to traditional asphalt-saturated felt paper. It is made from a blend of synthetic materials, such as polyethylene, polypropylene, or a combination of both. The manufacturing process involves weaving or laminating these materials to create a robust and highly durable underlayment product.

Many roofers are opting for synthetic roofing underlayment for increased water resistance and protection from the weather. These items are typically made of long-lasting polymers, which enhance strength and lifespan. This type of underlayment is often moisture-resistant, and when properly put, it provides superior weather protection than felt.

Because synthetic roofing underlayment materials are not specified, different producers may make their products differently, resulting in varying levels of performance. Do your homework and consult with a reputable contractor who can assist you in picking the best roofing materials to protect your home.

Key Advantages Of Synthetic Roof Underlayment

Synthetic roof underlayment has gained significant popularity in the roofing industry due to its numerous advantages over traditional asphalt-saturated felt paper. As an advanced alternative, synthetic underlayment offers several key benefits that make it a preferred choice for roofing professionals and homeowners alike.

In this section, we will delve into the essential advantages of synthetic roof underlayment, highlighting why it has become a crucial component in modern roofing systems.

Superior Strength And Durability

One of the primary advantages of synthetic roof underlayment is its exceptional strength and durability. Unlike traditional felt paper, which can be prone to tearing and punctures during installation or exposure to adverse weather conditions, synthetic underlayment is designed to be highly resistant to damage.

The synthetic materials used in its construction, such as polyethylene or polypropylene, provide a robust and tear-resistant barrier, ensuring long-lasting protection for the roof.

Lightweight And Easy Handling

Synthetic roof underlayment is significantly lighter than traditional felt paper, making it easier for roofing contractors to handle and install. Its lightweight nature reduces the physical strain on workers during installation and transportation to the rooftop. Moreover, the ease of handling allows for quicker and more efficient installation, saving time and labor costs during the roofing project.

Slip-Resistant Surface

Safety is paramount during any roofing installation, especially on steep-slope roofs. Synthetic roof underlayment is designed with a slip-resistant surface, providing added safety for roofing contractors while they work at elevated heights. The slip-resistant feature helps prevent accidents caused by slipping, particularly when working in wet or adverse weather conditions.

UV Resistance

Exposure to sunlight and UV radiation can cause traditional felt paper to deteriorate over time, potentially compromising the roof's integrity. Synthetic roof underlayment is engineered to be UV resistant, allowing it to withstand prolonged exposure to sunlight without degradation. This UV resistance ensures that the underlayment remains stable and effective in protecting the roof decking until the roofing materials, such as shingles or tiles, are installed.

Water And Weather Resistance

A crucial function of any roof underlayment is to act as a moisture barrier, protecting the roof decking and the interior of the building from water infiltration. Synthetic underlayment excels in this regard, offering excellent water resistance and weatherproofing capabilities.

Its advanced design and material composition ensure that it effectively repels water, preventing potential damage caused by leaks or moisture seepage during the roofing installation process.

Breathable And Vapor Permeable

Some high-quality synthetic roof underlayment products are designed to be breathable and vapor permeable. This feature allows moisture vapor to escape from the roof deck, preventing condensation buildup and potential damage to the roofing materials. A breathable underlayment promotes proper ventilation, reducing the risk of mold or rot in the roof structure.

Tear Lines And Easy Installation

Many synthetic roof underlayment products come with pre-printed nailing guides or tear lines, simplifying the installation process for roofing contractors. These guidelines help ensure consistent and precise installations, reducing the likelihood of errors and minimizing waste during the roofing project.

Applications Of Synthetic Roof Underlayment

Synthetic roof underlayment has become a versatile and widely used component in modern roofing systems. Its advanced design and superior properties make it suitable for various roofing applications. In this article, we will explore the key applications of synthetic roof underlayment, highlighting the areas where it excels in providing reliable protection and enhancing the overall performance of the roofing system.

New Roof Construction

One of the primary applications of synthetic roof underlayment is in new roof construction. When installing a new roof, choosing the right underlayment is crucial to ensure the roof's longevity and durability.

Synthetic underlayment's exceptional strength and tear resistance make it an ideal choice for this application. Its lightweight nature also makes it easier to transport to the rooftop, facilitating the installation process for roofing contractors.

Roof Replacement And Re-Roofing Projects

Synthetic roof underlayment is a preferred option for roof replacement and re-roofing projects. When tearing off an existing roof to install a new one, synthetic underlayment can be applied over the old roofing material. Its durability and resistance to tears and punctures provide a reliable base for the new roofing system. This application is particularly beneficial in situations where complete removal of the old roof is not feasible or practical.

Temporary Roof Covering

In some roofing projects, the installation process may span several days or require interruptions due to adverse weather conditions or other unforeseen circumstances. Synthetic roof underlayment can serve as a temporary roof covering during such extended periods. Its water resistance properties protect the roof deck and the interior of the building from potential water damage until the roofing project can be completed.

Steep-Slope Roofing

Steep-slope roofing installations can be challenging and require materials that offer excellent grip and safety for roofing contractors. Synthetic roof underlayment's slip-resistant surface makes it particularly suitable for steep-slope roofing applications. The added safety feature reduces the risk of accidents during installation, providing peace of mind for both workers and project managers.

Low-Slope Roofing

While synthetic underlayment is commonly associated with steep-slope roofing, it can also be used in low-slope roofing applications. Its exceptional water resistance and weatherproofing capabilities ensure reliable protection for low-slope roofs, preventing potential leaks and moisture-related issues.

Residential And Commercial Roofing

Synthetic roof underlayment is equally well-suited for both residential and commercial roofing projects. Its versatility and performance characteristics make it a viable choice for roofs of all sizes and types. Whether it's a single-family home or a large commercial building, synthetic underlayment offers reliable protection and enhances the overall performance of the roofing system.

Metal Roofing

Metal roofing is a popular choice for its durability and longevity. Synthetic roof underlayment complements metal roofing installations by providing an added layer of protection against potential water infiltration. Its tear-resistant properties ensure that the metal roofing materials remain securely in place, even in areas with high wind exposure.

Installation

Preparing The Roof Deck

Before installing synthetic underlayment, ensure that the roof deck is clean, dry, and free from debris. Remove any existing roofing materials, nails, or staples that could affect the underlayment's adhesion. The roof deck should be flat and even to facilitate a smooth installation.

Unrolling And Positioning

Unroll the synthetic underlayment along the eaves of the roof, starting from one end and working your way to the other. Allow the underlayment to overhang the roof edge to ensure proper water drainage. Position the underlayment evenly, taking care to avoid wrinkles or creases that could compromise its integrity.

Nailing Or Fastening

Secure the synthetic underlayment to the roof deck using appropriate fasteners. Roofing nails or plastic cap nails are commonly used for this purpose. Follow the manufacturer's guidelines for the recommended nail spacing and pattern to ensure proper attachment and to prevent wind uplift during severe weather conditions.

Overlapping

Overlap adjacent sheets of synthetic underlayment according to the manufacturer's instructions. Proper overlapping is essential to create a continuous moisture barrier and to prevent water infiltration at the seams. Generally, a minimum overlap of 3-6 inches is recommended, depending on the specific underlayment product.

Sealing Around Penetrations

Properly seal around roof penetrations, such as vents, chimneys, and skylights, to prevent water from infiltrating beneath the underlayment. Use appropriate sealants and flashing materials to create a watertight seal at these critical areas.

Valley Installation

In valleys or other areas prone to water flow, install the synthetic underlayment in a manner that promotes proper water drainage. The underlayment should be carefully tucked into the valleys to direct water away from vulnerable areas.

Maintenance

Regular Inspections

Regular inspections are essential to identify any signs of damage or wear on the synthetic underlayment. Inspect the roof after severe weather events, such as storms or heavy rains, to ensure that the underlayment has not sustained any tears or punctures.

Addressing Damage Promptly

If any damage, tears, or punctures are identified during inspections, address them promptly. Prompt repairs or replacements will help maintain the underlayment's effectiveness in protecting the roof deck and interior of the building from water infiltration.

Preventing Accumulation Of Debris

Clear any accumulated debris, such as leaves, branches, or dirt, from the roof surface regularly. Accumulated debris can trap moisture and cause premature wear on the underlayment.

Ensuring Proper Ventilation

Adequate roof ventilation is essential to prevent moisture buildup in the roof system. Proper ventilation helps maintain the integrity of the synthetic underlayment and prevents issues such as condensation or mold growth.

Observing Manufacturer's Recommendations

Follow the manufacturer's maintenance recommendations and guidelines for the specific synthetic underlayment product. Each product may have unique maintenance requirements, and adhering to these guidelines will ensure optimal performance and longevity.

What Are The Best Types Of Synthetic Roof Underlayment? Pros, Cons, And Cost.

People Also Ask

What Is Synthetic Roof Underlayment?

Synthetic roof underlayment is an advanced alternative to traditional asphalt-saturated felt paper used as a protective layer between the roof decking and roofing materials. It is made from a blend of synthetic materials like polyethylene or polypropylene, providing superior strength, durability, and resistance to tears and punctures.

What Are The Advantages Of Synthetic Roof Underlayment?

Synthetic roof underlayment offers several advantages, including superior strength and durability, lightweight and easy handling during installation, slip-resistant surface for increased worker safety, UV resistance to withstand prolonged sunlight exposure, and excellent water and weather resistance to protect the roof decking during installation.

Where Can Synthetic Roof Underlayment Be Used?

Synthetic roof underlayment is suitable for various roofing applications, including new roof construction, roof replacement and re-roofing projects, temporary roof covering during extended roofing projects, and steep-slope roofing installations.

How Is Synthetic Roof Underlayment Installed?

Synthetic roof underlayment is installed following similar guidelines to traditional felt paper. Roofing contractors should refer to the manufacturer's instructions for proper installation techniques, which may include using tear lines and pre-printed nailing guides for precise and efficient installations.

How Should Synthetic Roof Underlayment Be Maintained?

Regular roof maintenance is essential to ensure the longevity and effectiveness of synthetic roof underlayment. Periodic inspections should be conducted to check for tears, punctures, or any signs of damage. If any issues are found, prompt repairs or replacements should be carried out to maintain the underlayment's protective capabilities.

Conclusion

Synthetic roof underlayment is a technologically advanced and highly efficient alternative to traditional asphalt-saturated felt paper. Its superior strength, durability, lightweight nature, and resistance to water, UV rays, and tear make it an ideal choice for modern roofing projects.

Roofing contractors and homeowners alike benefit from the advantages it offers in terms of ease of installation, worker safety, and long-term roof protection. As the roofing industry continues to embrace innovation, synthetic roof underlayment has undoubtedly proven itself as a valuable and reliable component for ensuring the integrity and longevity of roofs in various construction projects.

Latest Articles

Popular Articles