Consistent Heating Cooling River - Achieving Sustainable Temperature Control In Urban Environments

In urban environments, maintaining consistent heating and cooling is a significant challenge due to the complexity of energy systems and the impact of the urban heat island effect. However, innovative approaches such as the concept of a consistent heating cooling river are emerging as potential solutions. This article will delve into the concept of a consistent heating-cooling river, its benefits, and the technologies involved in achieving sustainable temperature control in urban areas.

Author:George EvansJun 02, 2023129.8K Shares1.7M Views

In urban environments, maintaining consistent heating and cooling is a significant challenge due to the complexity of energy systems and the impact of the urban heat island effect. However, innovative approaches such as the concept of a consistent heating cooling riverare emerging as potential solutions. This article will delve into the concept of a consistent heating-cooling river, its benefits, and the technologies involved in achieving sustainable temperature control in urban areas.

What Is A Consistent Heating-Cooling River?

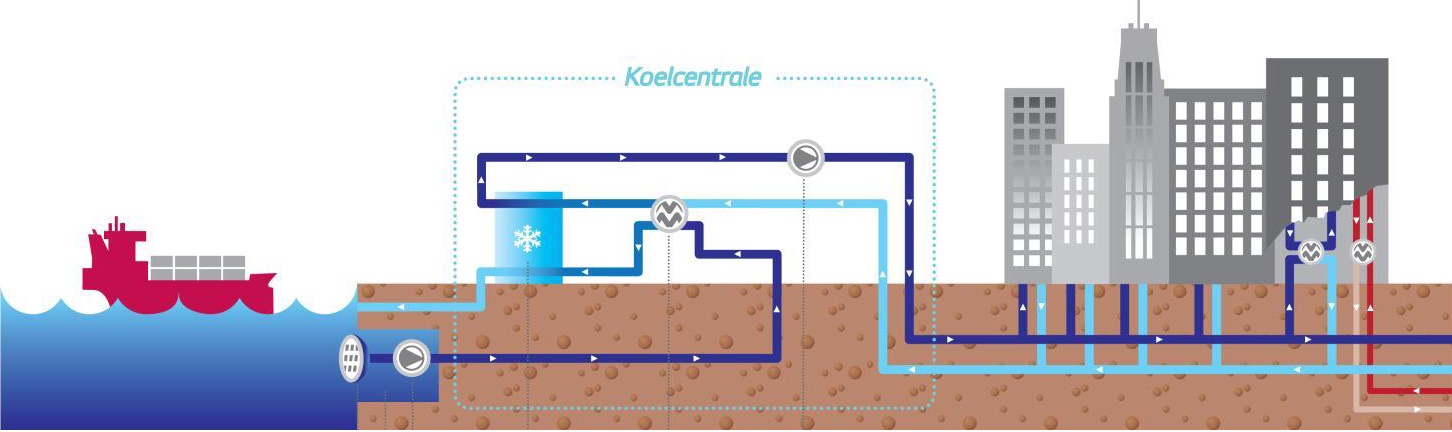

A consistent heating-cooling river is a sustainable energy system that utilizes natural water bodies, such as rivers, lakes, or underground aquifers, as heat exchange sources to provide heating and cooling for nearby buildings and infrastructure. The concept leverages the thermal energy stored in water bodies to maintain a consistent temperature throughout the year, offering a renewable and efficient alternative to traditional heating and cooling systems.

Benefits Of A Consistent Heating-Cooling River

A consistent heating-cooling river is an innovative and sustainable approach to temperature control in urban areas. By leveraging the thermal energy stored in natural water bodies, such as rivers, lakes, or underground aquifers, this system offers numerous benefits that contribute to energy efficiency, environmental sustainability, and improved comfort for buildings and their occupants. This article explores the key benefits of a consistent heating-cooling river system.

Energy Efficiency

One of the primary advantages of a consistent heating-cooling river system is its exceptional energy efficiency. By utilizing natural water bodies as heat sources or sinks, this system reduces reliance on traditional heating and cooling methods that often rely on fossil fuel combustion.

Water has a high heat capacity, allowing it to store and transport thermal energy effectively. By extracting heat from the water during the cooling season and transferring it to buildings for air conditioning, the system minimizes energy consumption and promotes efficient use of resources.

Renewable Energy

A consistent heating-cooling river system relies on renewable energy sources. It harnesses the natural temperature differential between the water and the surrounding environment to provide heating and cooling.

By tapping into the renewable thermal energy stored in water bodies, this system contributes to a more sustainable energy mix. It reduces greenhouse gas emissions associated with traditional heating and cooling systems, helping to mitigate climate change and create more environmentally friendly urban environments.

Environmental Sustainability

The use of a consistent heating-cooling river system significantly reduces the environmental impact of temperature control in urban areas. By utilizing renewable energy sources, the system minimizes the carbon footprint and air pollution associated with conventional heating and cooling methods.

It also helps mitigate the urban heat island effect, a phenomenon where cities experience higher temperatures due to the abundance of heat-absorbing materials. By utilizing the cooling potential of water bodies, the system reduces ambient temperatures and contributes to a more comfortable and sustainable urban environment.

Enhanced Resilience

A consistent heating-cooling river system enhances the resilience of urban areas to climate change and extreme weather events. Water bodies exhibit thermal inertia, meaning they can store and release thermal energy over an extended period.

This characteristic helps buffer extreme temperature variations, providing a more stable and reliable heating and cooling source throughout the year. The system can withstand temperature fluctuations and maintain a consistent indoor climate, contributing to occupant comfort and well-being.

Cost Savings

Although the initial installation costs of a consistent heating-cooling river system may be higher than traditional systems, it offers long-term cost savings. The utilization of renewable energy sources reduces energy consumption, resulting in lower utility bills for heating and cooling.

Building owners and occupants can benefit from reduced operational costs over the system's lifespan. Additionally, the stability and reliability of the system can lead to fewer maintenance and repair expenses, further contributing to cost savings.

Exploring The Technologies Behind Consistent Heating-cooling River Systems

A consistent heating-cooling river system utilizes a combination of technologies to effectively extract and transfer thermal energy from natural water bodies, such as rivers, lakes, or underground aquifers, to provide heating and cooling for buildings and infrastructure in urban areas.

These technologies play a crucial role in maximizing energy efficiency, optimizing heat exchange, and ensuring the reliable operation of the system. This article explores the key technologies involved in a consistent heating-cooling river system.

Heat Pumps

Heat pumps are central components of a consistent heating-cooling river system. They are responsible for extracting heat from the water during the cooling season and transferring it to the buildings for air conditioning.

In the heating season, the heat pumps reverse the process, extracting heat from buildings and releasing it back into the water. Heat pumps use the principles of refrigeration cycles and compressors to facilitate heat transfer, providing an efficient means of utilizing the thermal energy stored in water bodies.

Heat Exchangers

Heat exchangers are essential components of a consistent heating-cooling river system as they enable the transfer of thermal energy between the water and the heating or cooling distribution system.

These devices ensure efficient heat exchange while maintaining water quality and minimizing potential environmental impacts. Heat exchangers come in various configurations, including shell-and-tube, plate, or coaxial designs, depending on the specific requirements of the system.

Distribution Networks

Distribution networks consist of a network of pipes that carry the heating or cooling medium from the water source to the buildings requiring temperature control. These networks play a critical role in transporting thermal energy efficiently and effectively. Proper design and insulation of the distribution networks are crucial to minimize heat loss or gain during transmission, ensuring that the desired temperature is maintained throughout the system.

Monitoring And Control Systems

Advanced monitoring and control systems are employed to optimize the performance of a consistent heating-cooling river system. Real-time monitoring of temperature differentials, flow rates, and energy consumption allows for precise control and efficient operation. These systems ensure that the heating and cooling demands of buildings are met while minimizing energy waste and maintaining optimal comfort levels.

Integration With Building Systems

To fully leverage the benefits of a consistent heating-cooling river system, it must be integrated with the building's internal heating, ventilation, and air conditioning (HVAC) systems.

This integration involves incorporating heat pump systems, heat exchangers, and distribution networks into the building designs and ensuring compatibility with existing HVAC systems. Coordination between the consistent heating-cooling river system and the building's internal systems is crucial for seamless operation and optimal energy efficiency.

Thermal Storage Systems (Optional)

In some cases, consistent heating-cooling river systems may incorporate thermal storage technologies. Thermal storage allows for the accumulation of excess thermal energy during periods of low demand or optimal conditions.

This stored energy can be utilized during peak demand periods or when the temperature differential between the water source and the building is insufficient. Thermal storage systems can include technologies such as insulated tanks or underground thermal reservoirs.

Renewable Energy Sources

While not a specific technology within the system, the utilization of renewable energy sources is fundamental to a consistent heating-cooling river system. By harnessing the thermal energy stored in water bodies, the system reduces reliance on fossil fuels, contributing to a more sustainable energy mix and minimizing greenhouse gas emissions.

People Also Ask

What Are The Benefits Of A Consistent Heating-cooling River System?

The benefits of a consistent heating-cooling river system include improved energy efficiency, reliance on renewable energy sources, reduced environmental impact, enhanced resilience to climate change, and potential cost savings.

What Technologies Are Involved In A Consistent Heating-cooling River System?

The technologies involved in a consistent heating-cooling river system include heat pumps, heat exchangers, distribution networks, monitoring and control systems, and integration with building systems.

How Does A Consistent Heating-cooling River System Work?

A consistent heating-cooling river system works by extracting heat from a natural water body during the cooling season using heat pumps, which is then transferred to buildings for air conditioning. In the heating season, the heat pumps reverse the process, extracting heat from buildings and releasing it back into the water.

Are There Any Successful Case Studies Of Implementing A Consistent Heating-cooling River System?

Yes, there are successful case studies of implementing consistent heating-cooling river systems in cities like Stockholm, Sweden, where the Värtan River is utilized as a sustainable energy source for heating and cooling nearby buildings. These systems have demonstrated improved energy efficiency and environmental sustainability.

Conclusion

A consistent heating cooling river system offers a sustainable and efficient solution for achieving temperature control in urban environments. By harnessing the renewable thermal energy stored in natural water bodies, such as rivers or lakes, this innovative approach reduces reliance on traditional heating and cooling systems that contribute to greenhouse gas emissions.

Successful case studies in various cities highlight the viability and effectiveness of this approach. The implementation of consistent heating-cooling river systems represents a significant step towards sustainable urban development and demonstrates the potential for innovative solutions in addressing the challenges of heating and cooling in urban areas.

George Evans

Author

George Anderson, an exceptional architectural designer, envisions and brings to life structures that transcend the realm of imagination. With an unwavering passion for design and an innate eye for detail, George seamlessly blends form and function, creating immersive spaces that inspire awe.

Driven by a deep appreciation for the interplay of space, light, and materials, George's innovative approach redefines the possibilities of architectural design. His visionary compositions leave an indelible mark, evoking a sense of wonder and transforming the built environment.

George Anderson's transformative designs and unwavering dedication continue to shape the architectural landscape, pushing the boundaries of what is possible and inspiring generations to come.

Latest Articles

Popular Articles