Robotics In Construction - A Game Changer In The Industry

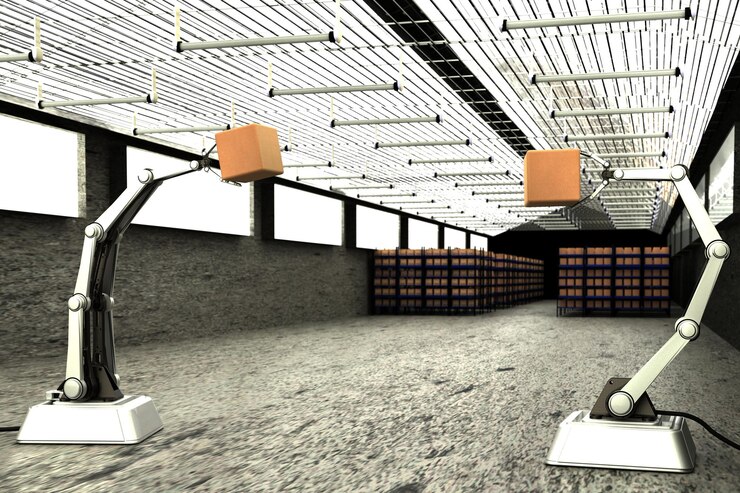

Robotics is no longer a sci-fi concept; it has become a reality in the construction industry. The use of robotics in construction is on the rise, and it is transforming the way construction projects are being planned and executed.

Author:George EvansApr 11, 202322 Shares988 Views

Robotics is no longer a sci-fi concept, it has become a reality in the construction industry. The use of robotics in constructionis on the rise and it is transforming the way construction projects are being planned and executed.

The integration of robotics in the construction industry has led to an increase in safety, efficiency, and accuracy.

In this article, we will explore the different applications of robotics in construction and how it is revolutionizing the industry.

The Applications Of Robotics In Construction

1. Automated Bricklaying

The use of robots in automated bricklaying is becoming increasingly popular in the construction industry. These robots can lay bricks faster and more accurately than human laborers.

They can work 24/7 without getting tired, which means that they can complete projects in a shorter amount of time. These robots are equipped with cameras and sensors that can detect and adjust to changes in the environment, ensuring precision in bricklaying.

2. 3D Printing

Robots can be used for 3D printing, which can reduce the time and cost of construction projects.

3D printing can be used to create complex structures that would otherwise be difficult or impossible to build with traditional construction methods.

Additionally, it can minimize waste and reduce the carbon footprint of construction projects.

3. Demolition

Robots are also being used for demolition purposes. They can quickly and efficiently demolish buildings and structures, reducing the risk of injury to human laborers. Robots can also be used in areas that are difficult to access or too dangerous for humans.

4. Inspection

Robots can be used for inspection purposes in construction projects. They can crawl into small spaces and provide visual data on the condition of buildings and structures.

This can help identify potential problems before they become serious issues, and ensure that buildings are safe and up to code.

How is robotics impacting the construction industry?

Types Of Robots Used In Construction

There are various types of robots that are used in construction to improve efficiency, safety, and precision. Here are some of the common types:

- Autonomous robots:These robots are self-guided and can perform specific tasks without human intervention. For example, they can be used to move materials, lay bricks, or perform inspections.

- Drones: Drones can be used to survey construction sites, capture images and videos, and monitor progress. They can also be used to transport materials to difficult-to-reach areas of the construction site.

- Robotic arms:These are similar to industrial robots and are designed to perform tasks that require a high degree of accuracy and precision. They can be used for tasks such as drilling, welding, and painting.

- Exoskeletons:These are wearable robots that can help construction workers lift heavy objects and perform other physically demanding tasks. They can help reduce the risk of injury and improve productivity.

- 3D printers:3D printing technology can be used to create prefabricated building components, such as walls, roofs, and floors. This can help reduce construction time and costs.

Overall, the use of robots in construction is becoming increasingly common as companies look to improve safety, efficiency, and productivity.

Benefits Of Robotics In Construction

There are numerous benefits of using robotics in construction, including:

Increased Efficiency

One of the main advantages of robotics in construction is the increased efficiency it provides.

By using robots for tasks such as demolition, bricklaying, and 3D printing, construction companies can complete projects more quickly and with greater accuracy.

Robots can work 24/7, without the need for breaks or rest, allowing for faster completion of projects.

Improved Safety

Construction is a high-risk industry, with accidents and injuries a common occurrence. By using robots for tasks such as site surveys and demolition, workers can be kept out of harm's way.

Robots can also be used to lift and move heavy materials, reducing the risk of injury to workers.

Cost Savings

Although the initial cost of purchasing and installing robotics equipment can be high, over the long term, it can lead to significant cost savings.

Robots can work faster and more efficiently than humans, reducing the need for manual labor and increasing productivity.

This can lead to cost savings in the form of reduced labor costs and faster project completion times.

Challenges Of Robotics In Construction

1. Cost

The initial cost of robots can be high, which may deter some construction companies from using them. Additionally, maintenance costs and software updates can add to the overall cost of using robots in construction.

2. Integration With Existing Systems

Robots need to be integrated with existing construction systems and processes, which can be challenging.

This requires significant planning and coordination to ensure that robots can work efficiently and effectively with human laborers.

3. Safety Concerns

While robots can improve safety in construction, they can also pose safety risks if not properly maintained or operated.

There is a need for strict safety regulations and protocols to ensure that robots are operated safely in construction sites.

The Future Of Robotics In Construction

Despite these challenges, the future of robotics in construction looks bright. As technology continues to advance, robots will become more versatile, flexible, and affordable.

They will also become more integrated with other technologies, such as machine learning and artificial intelligence, which will enable them to learn and adapt to new tasks and environments.

The use of robotics in construction is still in its early stages, but it has the potential to revolutionize the industry.

By improving efficiency, safety, and cost-effectiveness, robots are changing the way we build our buildings and infrastructure.

As construction companies continue to embrace robotics technology, we can expect to see even more innovation and transformation in the years to come.

People Also Ask

How Are Robots Used In The Construction Industry?

Robots are used in the construction industry to perform a variety of tasks, including bricklaying, demolition, excavation, and even painting.

They are designed to operate in dangerous and difficult environments, which can help improve worker safety and efficiency.

For example, bricklaying robots are capable of laying up to 1,000 bricks per hour, which is significantly faster than a human worker.

What Are The Benefits Of Using Robots In Construction?

The benefits of using robots in construction include improved safety, increased productivity, reduced labor costs, and greater accuracy.

Robots can perform repetitive and dangerous tasks that would otherwise be difficult or impossible for humans, which can help reduce the risk of injuries on construction sites.

They can also work 24/7, which can help speed up construction projects and reduce labor costs.

What Are The Different Types Of Robots Used In Construction?

There are several different types of robots used in construction, including bricklaying robots, demolition robots, excavation robots, and painting robots.

Some robots are designed to operate on tracks or wheels, while others are equipped with legs or even arms and hands, allowing them to perform complex tasks.

How Do Robots Improve Safety In Construction?

Robots improve safety in construction by performing dangerous and repetitive tasks that would otherwise be done by human workers. This helps reduce the risk of injuries and fatalities on construction sites.

Robots are also capable of working in hazardous environments, such as areas with high levels of radiation or toxic chemicals, which can further improve worker safety.

What Is The Future Of Robotics In Construction?

The future of robotics in construction is promising, with many experts predicting that robots will play an increasingly important role in the industry.

As technology advances, robots will become even more capable of performing complex tasks, and they will be able to work alongside human workers to improve safety and productivity.

Final Words

Robotics in construction has the potential to revolutionize the industry by improving safety, increasing efficiency, and reducing costs. As technology continues to advance, it is likely that we will see more and more robots and automation integrated into construction processes.

However, it is important to note that the implementation of robotics in construction is not without its challenges, including high costs, resistance to change, and the need for specialized training.

Nonetheless, with careful planning and investment, the benefits of robotics in construction can far outweigh the challenges.

As the demand for sustainable and innovative building solutions increases, the role of robotics in construction is set to become increasingly important in the years to come.

George Evans

Author

George Anderson, an exceptional architectural designer, envisions and brings to life structures that transcend the realm of imagination. With an unwavering passion for design and an innate eye for detail, George seamlessly blends form and function, creating immersive spaces that inspire awe.

Driven by a deep appreciation for the interplay of space, light, and materials, George's innovative approach redefines the possibilities of architectural design. His visionary compositions leave an indelible mark, evoking a sense of wonder and transforming the built environment.

George Anderson's transformative designs and unwavering dedication continue to shape the architectural landscape, pushing the boundaries of what is possible and inspiring generations to come.

Latest Articles

Popular Articles