Sustainable Car Manufacturing Facilities - Paving The Green Road Ahead

The automotive industry, known for its significant energy consumption and emissions, is no exception. One remarkable approach gaining traction is the development of sustainable car manufacturing facilities – a fusion of architecture, engineering, and environmental consciousness.

Author:George EvansJun 29, 202323.1K Shares398.8K Views

In an era marked by increasing environmental awareness and a global push toward sustainability, industries across the board are seeking innovative ways to reduce their carbon footprintand minimize their impact on the planet. The automotive industry, known for its significant energy consumption and emissions, is no exception. One remarkable approach gaining traction is the development of sustainable car manufacturing facilities,a fusion of architecture, engineering, and environmental consciousness.

Understanding Sustainable Manufacturing In The Auto Industry

Understanding the essence of sustainable manufacturing in the automotive sector necessitates an exploration of its core principles. In essence, sustainable or 'green' auto manufacturing strives to minimize production waste and the environmental impact associated with vehicle production. This objective is achieved through the recalibration of product designs, manufacturing processes, and workflow methodologiesto align with environmentally conscious standards.

The rewards of this approach are manifold. Sustainable auto manufacturers often witness an upswing in brand value and expanded market opportunities stemming from their conscientious choices. By curbing wastage and embracing material reuse, they can also effectively trim their expenditures.

Moreover, manufacturers adopting environmentally sustainable practices are less encumbered by regulatory constraints or legal entanglements tied to environmental pollution. As investors progressively shift away from environmentally detrimental entities and fossil fuel-dependent enterprises, these manufacturers find themselves better poised to navigate evolving industry dynamics and adapt seamlessly to indispensable changes.

The Automotive Industry's Evolution Towards Sustainable Car Manufacturing Facilities

The automotive industry is undergoing a transformative shift by integrating sustainable materials into the production of vehicles. This transition towards sustainability is propelled by escalating consumer preferences for environmentally conscious options, regulatory mandates, and the mounting influence of investor pressures.

A compelling instance of this transition is the escalating utilization of recycled materials in crafting car components. Automotive manufacturers are harnessing recycled plastics, rubber, and metals to fabricate various vehicle parts, including bumpers, tires, and door panels. This strategic move not only curtails waste generation but also conserves precious natural resources, exemplifying the industry's commitment to sustainable practices.

Furthermore, automotive giants are weaving sustainability into their manufacturing processes by adopting renewable energy sources. Substantial investments are directed towards solar power, wind turbines, and other renewable energy platforms to fuel their factories, effectively reducing their dependence on fossil fuels. This dual-pronged strategy not only diminishes carbon emissions but also proves to be a fiscally responsible approach to energy procurement, fostering a greener production cycle.

Innovative technologies are also at the forefront of automotive companies' sustainable endeavors, aimed at enhancing vehicle efficiency and minimizing emissions. The surge in popularity of electric cars stands as a remarkable testament to this trend, with their minimal emissions and exceptional efficiency ratings captivating consumers. Parallelly, automakers are propelling the advancement of autonomous driving technology, which holds the potential to optimize fuel consumption and further slash emissions, thereby establishing a comprehensive approach towards sustainability.

As the automotive industry embarks on this transformative journey, it strives to incorporate sustainable materials into its manufacturing processes, striking a harmonious chord between meeting consumer preferences for eco-friendliness and curtailing its environmental footprint. Through innovative strides and a steadfast commitment to sustainability, the industry is poised to redefine vehicular manufacturing for a greener future.

Greening The Assembly Line

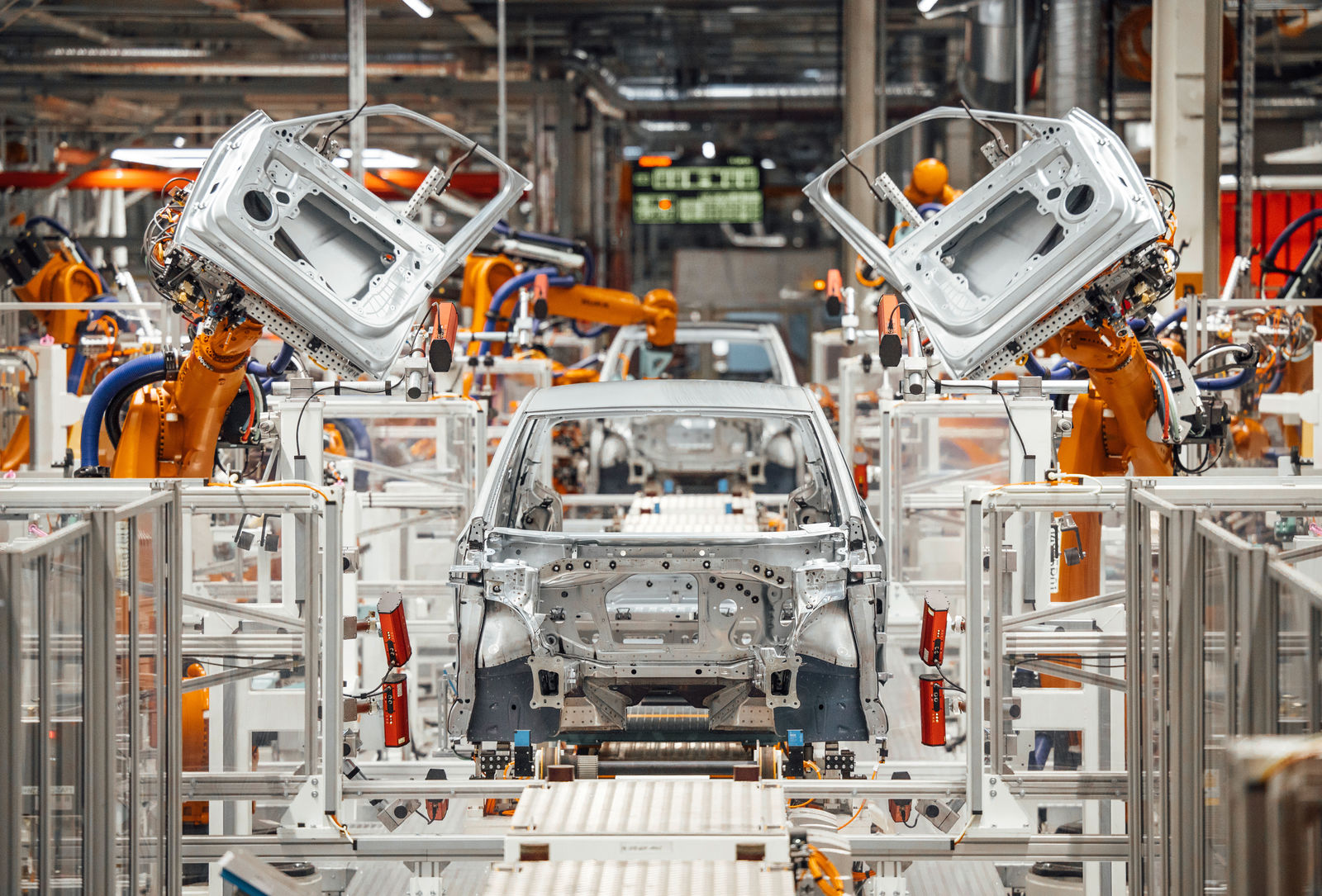

Traditional car manufacturing processes are notorious for their resource-intensive nature, consuming vast amounts of energy and generating substantial waste. The assembly line, a hallmark of industrial production, has long been associated with these energy-intensive methods. However, the landscape is shifting as sustainable car manufacturing facilities emerge as champions of change, redefining the assembly line concept with a steadfast commitment to embracing energy-efficient technologies and eco-friendly practices.

Energy-Efficient Design - Balancing Form And Function

At the heart of these sustainable facilities lies an emphasis on energy-efficient architectural design that goes beyond aesthetics. Architects and engineers collaborate meticulously to create structures that seamlessly blend functionality with sustainability. These architects are not just crafting buildings; they are sculpting solutions to reduce the environmental footprint of the entire production process. Digital printing is helping to address this goal, you can learn more about this technique incorporated into the car industry. By incorporating innovative design elements, they are reimagining the traditional industrial setting.

Harvesting Natural Light

One of the foundational principles is harnessing natural light to illuminate the factory floors. Expansive windows and strategically positioned skylights allow sunlight to flood the interior spaces, reducing the need for artificial lighting during daylight hours. This not only cuts down on energy consumption but also provides a more pleasant work environment for employees.

Solar Power Integration

The installation of solar panels is a prominent feature of energy-efficient design in these facilities. Rooftops are adorned with photovoltaic arrays that convert sunlight into electricity, which can then power various aspects of the manufacturing process. The symbiotic relationship between architecture and technology is evident in the seamless integration of these panels into the building's design, demonstrating that sustainability can be seamlessly woven into the fabric of the industry.

Innovative Insulation

Advanced insulation systems are employed to regulate temperature and reduce energy losses. These systems maintain a comfortable working environment while minimizing the need for excessive heating or cooling. By creating a stable climate within the facility, energy consumption for temperature control is significantly lowered, contributing to both cost savings and ecological benefits.

Waste Reduction And Recycling - Nurturing A Circular Economy

Waste reduction is a cornerstone of sustainability, and sustainable car manufacturing facilities are redefining waste management practices from the ground up. By championing a circular economy philosophy, these facilities are transforming waste into valuable resources, diminishing their impact on the environment and creating a paradigm shift in how industrial processes can be sustainable.

Resource Reconditioning

One of the most innovative practices within these facilities is the reconditioning of materials from previous vehicles. Salvaging components such as engines, transmissions, and electronic systems from end-of-life vehicles, these facilities extend the useful life of these parts, reducing the need for new manufacturing and minimizing waste.

Recycling Production Waste

Beyond reconditioning, the focus extends to recycling production waste. Materials like metals, plastics, and electronics are carefully separated, processed, and reintegrated into the production cycle. This approach drastically reduces the demand for virgin resources, conserving energy and minimizing the ecological footprint associated with sourcing raw materials.

Promotion Of Sustainable Consumption

Moreover, these facilities are drivers of sustainable consumption. By producing vehicles with a longer lifespan, they encourage consumers to hold on to their cars for more extended periods, reducing the overall demand for new vehicles and subsequently lowering the associated environmental impact of manufacturing.

The Road To Carbon Neutrality

Sustainable car manufacturing facilities are not content with merely reducing their impact on the environment; they are steadfastly dedicated to the pursuit of carbon neutrality. This ambitious goal involves not only minimizing carbon emissions but also actively offsetting the unavoidable emissions through various innovative means.

Renewable Energy Integration

One of the most significant strategies in the pursuit of carbon neutrality is the integration of renewable energy sources. Harnessing the power of the sun, wind, and water, these facilities are generating clean energy to power their operations. Solar panels glisten on the rooftops, capturing sunlight and transforming it into electricity, while wind turbines gracefully rotate, converting wind energy into a sustainable power source. By integrating these renewable energy sources into the manufacturing process, the reliance on fossil fuels is diminished, resulting in a substantial reduction in carbon emissions.

Carbon Offsetting Initiatives

Recognizing that achieving absolute zero emissions might be a complex endeavor, sustainable car manufacturing facilities are actively engaging in carbon offsetting initiatives. The philosophy behind this approach is simple yet powerful – for every unit of carbon emitted during production, an equivalent amount is removed from the atmosphere through environmentally beneficial projects. This can take the form of reforestation efforts, where trees are planted to absorb carbon dioxide, or investments in renewable energy projects that generate clean electricity. By embracing these offsetting initiatives, these facilities are taking responsibility for their environmental impact and contributing positively to the global fight against climate change.

Technological Innovations

Sustainability and cutting-edge technology often go hand in hand. Sustainable car manufacturing facilities are leveraging the latest technological advancements to revolutionize the way cars are made.

Smart Manufacturing Systems

In the heart of these facilities, the Fourth Industrial Revolution is taking center stage. Artificial intelligence, the Internet of Things (IoT), and data analytics converge to optimize production processes. These interconnected systems monitor energy consumption, predict maintenance needs, and optimize workflow efficiency, all while minimizing energy waste and reducing the carbon footprint. The fusion of intelligent technologies with sustainable manufacturing practices not only enhances productivity but also sets new standards for responsible and efficient production methods.

Closed-Loop Production

Another pioneering concept driving sustainable car manufacturing is closed-loop production. Traditionally, manufacturing processes were linear – materials were extracted, used, and discarded after their useful life. In contrast, closed-loop production is circular in nature. Components and materials are continually recycled within the manufacturing process, eliminating the need for new resources and significantly reducing waste. This closed-loop approach not only conserves valuable resources but also reduces the energy required to extract, transport, and process raw materials, thus further diminishing the ecological impact of car production.

Energy-Efficient Design - A Fusion Of Form And Function

At the core of these innovative facilities lies a profound emphasis on energy-efficient architectural design that seamlessly marries aesthetics with sustainability. Architects and engineers collaborate meticulously, not just to create structures, but to craft solutions that significantly reduce the environmental footprint of the entire production process. This synthesis of architectural artistry and ecological consciousness is shaping the manufacturing landscape in unprecedented ways.

Harvesting Natural Light For A Brighter Tomorrow

One of the cornerstones of energy-efficient design is the deliberate harnessing of natural light to illuminate the factory floors. With expansive windows that punctuate the walls and strategically positioned skylights, these facilities welcome sunlight to permeate every nook and cranny. The result? Reduced reliance on artificial lighting during daylight hours, leading to significant energy savings. Beyond the practical benefits, this approach also fosters a more inviting and productive work environment for employees.

Solar Power: A Beacon Of Clean Energy

The installation of solar panels takes center stage as a definitive feature of energy-efficient design. A choreography of photovoltaic arrays adorns rooftops, transforming sunlight into electricity that powers various aspects of the manufacturing process. This marriage of architectural aesthetics and technological prowess not only elevates the facility's visual appeal but also underscores the harmonious integration of sustainability into industrial functionality.

Pioneering Insulation Solutions

Revolutionizing insulation is another keystone in the foundation of energy-efficient design. Advanced insulation systems are employed to regulate temperatures efficiently and mitigate energy losses. The result is a controlled climate that minimizes the need for excessive heating or cooling. By maintaining a stable environment within the facility, energy consumption for temperature control is substantially reduced, leading to economic savings and a smaller ecological footprint.

A Blueprint For The Future

Sustainable car manufacturing facilities represent far more than a reduction in emissions and resource consumption; they stand as a groundbreaking blueprint for a future that is both ecologically conscious and industrially innovative. By weaving sustainability into the very fabric of their operations, these facilities are casting a forward-looking vision for the automotive industry, setting a precedent for responsible production practices that have far-reaching implications.

A Holistic Approach To Sustainability

At the heart of this blueprint is a commitment to holistic sustainability. These facilities embody the idea that every aspect of the manufacturing process can be optimized for efficiency and environmental stewardship. From architectural design to waste management, from renewable energy integration to closed-loop production, these facilities demonstrate that the pursuit of sustainability is not a compartmentalized endeavor but an all-encompassing ethos that informs every decision and action.

Championing Long-Term Viability

Central to this blueprint is the concept of long-term viability. These facilities are not merely aiming for short-term gains; they are committed to ensuring the long-term viability of the industry itself. By adopting practices that prioritize resource conservation, reduced emissions, and responsible consumption, they are paving the way for an automotive landscape that can thrive while minimizing its impact on the planet. This emphasis on longevity and foresight is a guiding principle that shapes their practices, products, and overall philosophy.

Industry Transformation

Sustainable car manufacturing facilities are catalysts for an industry-wide transformation that transcends factory walls. They recognize that their impact reaches far beyond their individual operations, inspiring an entire sector to rethink its approach to manufacturing and sustainability.

Redefining The Norm

Challenging the status quo is at the core of these facilities' mission. By establishing a new benchmark for sustainable manufacturing practices, they compel other manufacturers to evaluate their own processes and adopt more responsible methods. The competitive landscape shifts, with sustainability becoming a critical factor not only for consumer preference but for industry reputation as well. This transformation extends not only to direct competitors but also to the broader supply chain, creating a ripple effect that touches suppliers, partners, and stakeholders.

Collaboration And Knowledge Sharing

These facilities understand that transformation is most effective when shared. They actively engage in collaborative initiatives, sharing best practices, technological innovations, and insights with others in the industry. This collaborative ethos drives collective progress, accelerates the adoption of sustainable practices, and fosters a community committed to a greener future.

Inspiring Urban Planning: Beyond The Factory Walls

The influence of sustainable car manufacturing facilities transcends the confines of their physical spaces, permeating into the realms of urban planning, architectural design, and city development. They ignite a wave of inspiration that shapes how we envision and construct the urban landscapes of tomorrow.

A Green Ripple Effect

By demonstrating the harmonious fusion of industry and sustainability, these facilities inspire urban planners and architects to adopt eco-friendly principles in designing transportation hubs, charging infrastructure, and entire cities. The impact is tangible, with the integration of electric vehicle charging stations, car-sharing facilities, and pedestrian-friendly pathways becoming hallmarks of sustainable urban planning.

Building Eco-Conscious Cities

These facilities serve as living examples of how the industry can coexist with nature in urban settings. The architectural choices, renewable energy integration, and waste reduction strategies showcased within these facilities become guiding lights for architects and city planners aiming to design urban environments that prioritize environmental health. The result is a transformation of urban spaces into green, vibrant, and sustainable landscapes that cater to both the needs of residents and the well-being of the planet.

People Also Ask

How Can We Be Sustainable In Automobile Industry?

Being sustainable in the automobile industry involves adopting a series of strategies and practices that minimize the environmental impact of vehicle production and use. Some key approaches include:

- Material Selection: Opt for sustainable and recyclable materials in vehicle production to reduce the reliance on non-renewable resources.

- Energy Efficiency: Implement energy-efficient manufacturing processes and utilize renewable energy sources to power facilities.

- Reducing Emissions: Develop and promote electric and hybrid vehicles to lower emissions and reliance on fossil fuels.

- Lifecycle Analysis:Consider the entire lifecycle of vehicles, from production to disposal, to make informed decisions about environmental impacts.

- Recycling and Reuse: Design vehicles for easier disassembly and recycling, and promote the reuse of vehicle components.

- Eco-Friendly Design: Employ aerodynamic designs and lightweight materials to enhance fuel efficiency.

- Alternative Fuels: Explore and invest in alternative fuel sources like hydrogen and biofuels to diversify the energy mix.

What Is An Example Of Sustainability In The Automotive Industry?

One example of sustainability in the automotive industry is the integration of recycled materials in vehicle manufacturing. Many automakers are now incorporating recycled plastics, metals, and rubber into various components of vehicles, such as bumpers, interiors, and engine parts. This reduces the demand for virgin resources, minimizes waste, and lessens the overall environmental impact of manufacturing.

Who Is The Greenest Car Manufacturer?

Determining the "greenest" car manufacturer can vary depending on different factors and criteria. However, some well-known car manufacturers have demonstrated a strong commitment to sustainability:

- Tesla: Renowned for its electric vehicles and renewable energy solutions, Tesla is often considered a leader in green transportation.

- Toyota:A pioneer in hybrid technology with its Prius model, Toyota has a strong focus on sustainability and has made strides in fuel efficiency and alternative fuels.

- Nissan:Known for the electric Nissan Leaf, Nissan has contributed significantly to the adoption of electric vehicles.

- BMW:BMW has invested in electric and hybrid vehicles, sustainable materials, and renewable energy integration.

Conclusion

Sustainable car manufacturing facilities represent a bold stride toward a more sustainable and ecologically conscious future for the automotive industry. Through energy-efficient design, carbon neutrality pursuits, technological innovations, and a visionary outlook, these facilities are steering the industry toward a green horizon. As they continue to evolve, they are reshaping the very essence of car manufacturing, proving that environmental responsibility and industrial progress can indeed coexist.

Jump to

Understanding Sustainable Manufacturing In The Auto Industry

The Automotive Industry's Evolution Towards Sustainable Car Manufacturing Facilities

Greening The Assembly Line

The Road To Carbon Neutrality

Technological Innovations

Energy-Efficient Design - A Fusion Of Form And Function

A Blueprint For The Future

Industry Transformation

Inspiring Urban Planning: Beyond The Factory Walls

People Also Ask

Conclusion

George Evans

Author

George Anderson, an exceptional architectural designer, envisions and brings to life structures that transcend the realm of imagination. With an unwavering passion for design and an innate eye for detail, George seamlessly blends form and function, creating immersive spaces that inspire awe.

Driven by a deep appreciation for the interplay of space, light, and materials, George's innovative approach redefines the possibilities of architectural design. His visionary compositions leave an indelible mark, evoking a sense of wonder and transforming the built environment.

George Anderson's transformative designs and unwavering dedication continue to shape the architectural landscape, pushing the boundaries of what is possible and inspiring generations to come.

Latest Articles

Popular Articles